MIL-DTL-18266C

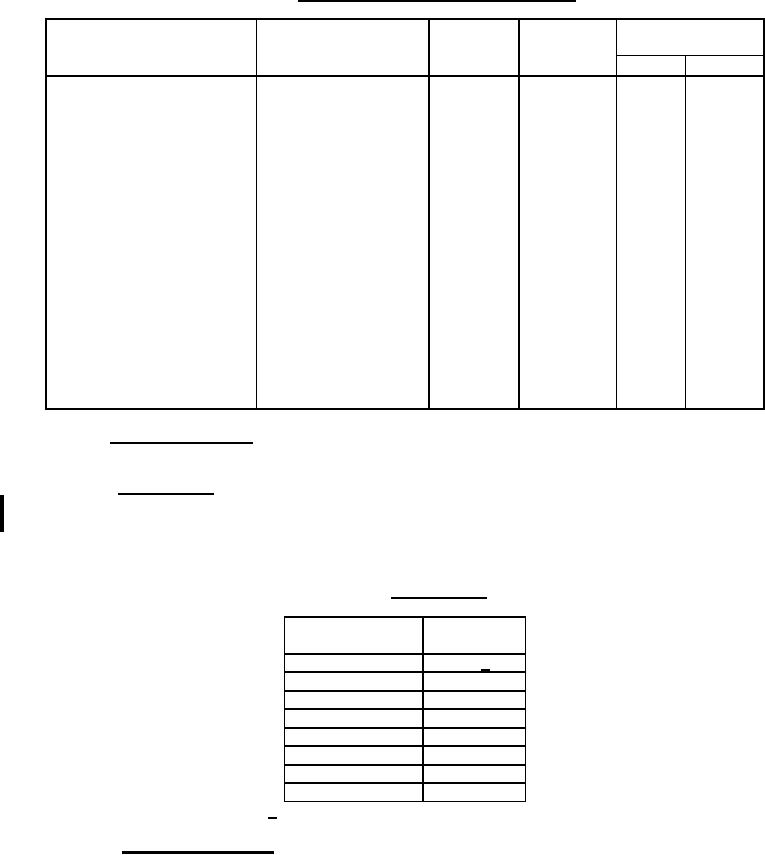

TABLE I. Qualification and Conformance inspection.

Conformance

inspection

Tests

Requirement

Test

Qualification

paragraph

paragraph

Individual

Sampling

Visual inspection

4.6.1

X

X

Electrical continuity

X

X

Transformer dc insulation

resistance

X

Frequency response

X

X

Distortion

X

X

Impedance

X

X

Overload

X

Humidity

X

Ambient temperature cycling

X

Visual inspection

X

Dielectric strength

X

Insulation resistance

X

Flame retardance

X

Tensile strength and

elongation

X

Flexing

X

Cold bend

X

4.3.2 Sampling inspections. Sampling inspections shall be as specified in table I and shall be made on

cord assemblies, which have been subjected to and passed the individual inspections.

4.3.2.1 Sampling plan. A sample of parts shall be randomly selected in accordance with table II. If one

or more defects are found, the contractor may rework it to correct the defects, or screen out the defective

units, and resubmit for reinspection. After screening and removal of defects, a new sample of parts shall

be randomly selected in accordance with table II. If one or more defects are found in the second sample,

the lot shall be rejected and shall not be supplied to this specification.

TABLE II. Sampling plan.

Lot size

Sample size

2 to 13

1/

14 to 150

13

151 to 280

20

281 to 500

29

501 to 1,200

34

1,201 to 3,200

42

3,200 to 10,000

50

Over 10,000

60

1/ Indicates entire lot must be inspected.

4.3.2.2 Disposition of samples. Samples, which have passed the inspection, may be delivered on the

contract, if the lot is accepted and the samples are still within specified electrical tolerances.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business