MIL-DTL-22442/35B

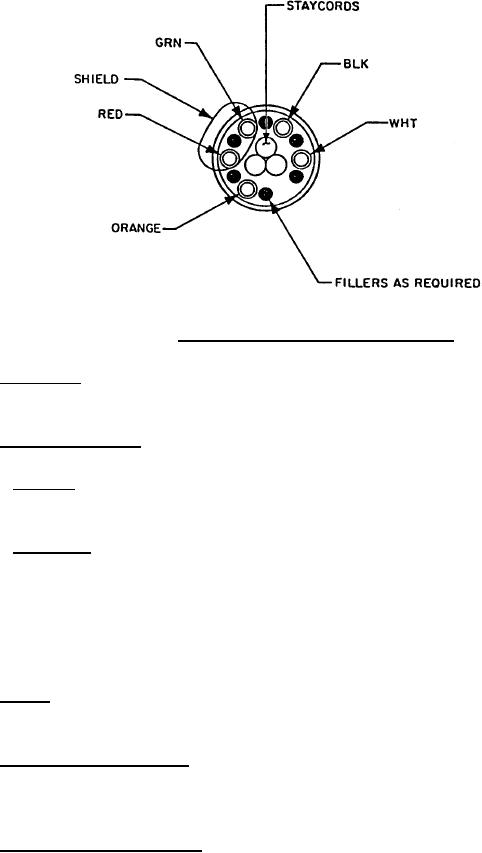

FIGURE 2. Cable construction P/N M22442/35-3.

* 3.2.4 Stay cords. The staycord shall have a minimum breaking strength of 25 pounds and

shall not abrade or otherwise damage the insulation when the cord is bent or stretched.

3.2.5 Jacketing materials.

3.2.5.1 Braided. For M22442/35-3, the cable shall be covered with a braided jacket

composed of black nylon, 210 denier, 3 ends, 24 carrier, approximately 30 picks per inch.

* 3.2.5.2 Elastomer. The M22442/35-1, and -2, cable shall have a flame retarding jacket

molded with a Type JS-l (SBR), JH (EPDM), JN, or JNL compound or a SBR natural blend

compound conforming to the performance requirements of MIL-C-55668. Flame retarding

polyurethane may also be used. The jacket is to be applied in a continuous extrusion process or

molded process directly onto the cable core. The jacket O.D. shall be in the range of .168 to .180

inch diameter with a jacket wall thickness of .016 to .025 inch.

3.2.6 Shield. The shielding will be wrapped shielding, 85-95 percent coverage, using

individual strands of size 36 AWG, nickel plated soft drawn copper strands.

* 3.2.7 Cable (cord) construction. Insulated conductors of cable assemblies M22442/35-1,

and M22442/35-2 shall have a one-inch nominal right hand lay. The M22442/35-1, M22442/35-

2, and M22442/35-3 red and green conductors shall be a shielded twisted pair.

3.2.8 Cable conductor separation. The finished cable may have all conductors within a

single outer jacket or may have conductors transition from a single outer jacket to separate outer

jackets for individual conductors or groups of conductors as specified in the contract or purchase

order. Whether in a single outer jacket or multiple outer jackets all other specification

requirements shall be met.

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business