MIL-DTL-3885G

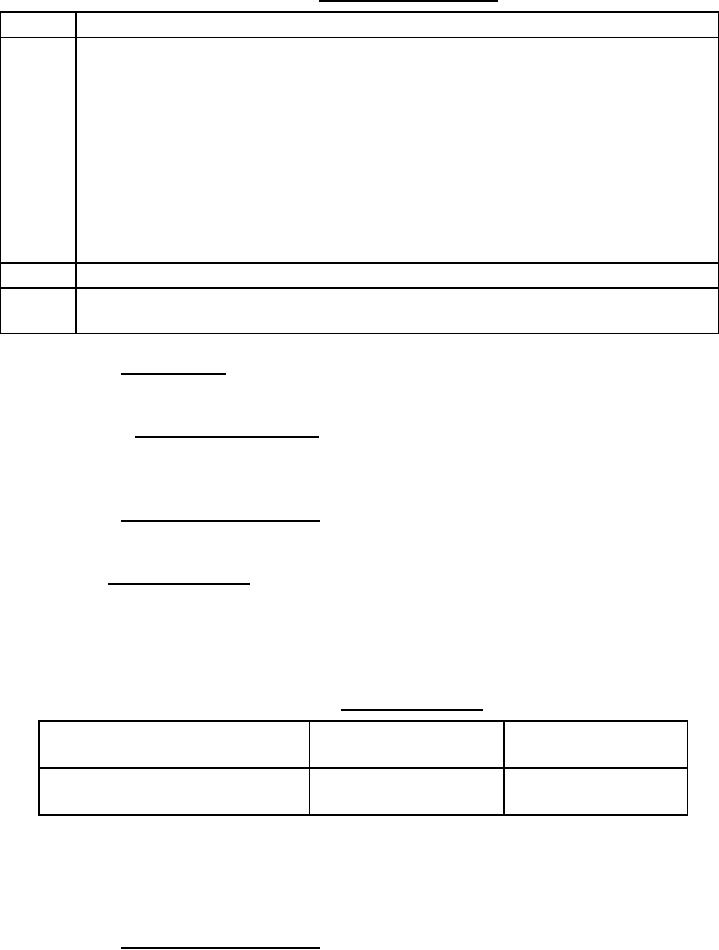

TABLE VI. Major and minor defects.

Major

Defect

Dimensions not as specified.

100

Material not as specified.

101

Scratches, cuts, and abrasions exposing conductors or conductor insulation.

102

Scratches, cuts, and abrasions, etc., exposing base metal.

103

Conductor or cable jackets showing through a molded surface.

104

Voids in the surface of the molded termination or section caused by insufficient filling.

105

Broken bond.

106

Incomplete bonding.

107

Electrical failure.

108

Missing parts.

109

Staycord not tied and secured in insert.

110

Minor

Defect

200

Scratches and abrasions of the molded termination or molded section.

201

Markings are dirty, smudged, or incorrectly placed, but legible.

4.3.2.2 Sampling plan. For the samples, the inspection level shall be level II in

accordance with ASQ Z1.4. The AQL shall be as specified in the contract (see 6.2).

4.3.2.2.1 Rejection of sample units. If a sample unit is rejected because it failed the

electrical tests specified in subgroup II, the contractor may withdraw the sample unit and rework

it to correct the defects. These units shall then be subjected to the inspection tests.

4.3.2.3 Disposition of sample units. Sample units that have passed group A inspection

are deliverable on the contract or order.

4.3.3 Group B inspection. Group B inspection, including sampling, shall conform to

table VII and to the procedures for small-sample inspection levels. Group B inspection shall be

performed on inspection lots that have passed group A inspection and on specimens selected from

units of product that have been subjected to and met the group A inspection. The special

inspection level shall be S-2.

TABLE VII. Group B inspection.

Requirement

Test method

Test requirement

paragraph

paragraph

Contact resistance variation 1

Interchangeability

1

This sampling may be performed by fabricating specimens of terminals attached to tinsel conductors,

provided the samples are prepared in the same manner using the same materials as in the cable assemblies

being subjected to group B inspection. The number of samples (terminals attached to tinsel conductors)

shall be predicated on the sample size selected for group B inspection multiplied by the number of

conductors within the cable assembly.

4.3.3.1 Disposition of sample units. Sample units that have passed group B inspection

may be delivered on the contract or order.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business