MIL-DTL-3885G

3.9.11 Reversion (polyurethane and polyacrylic compounds only). Polyurethane and

polyacrylic molding, potting, insulating, or jacketing compounds used on cable assemblies shall

be subjected to the test specified in 4.6.11 and as a result of the test the material shall not crack,

run, drip, or deform, and the hardness after conditioning shall be no more than 10 points below

the durometer hardness Shore "A" measured in 4.6.10. Except that for polyurethane compounds

cured with non-carcinogenic agents, the change shall be no more than 15 points.

3.10 Workmanship. Cable assemblies shall be manufactured in such a manner as to be

uniform in quality and shall be free from defects that will affect life or serviceability when tested

as specified in 4.7.

3.11 Recycled, recovered, or environmentally preferable materials. Recycled, recovered,

or environmentally preferable materials should be used to the maximum extent possible, provided

that the material meets or exceeds the operational and maintenance requirements, and promotes

economically advantageous life cycle costs.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are

classified as follows:

a. First article inspection (see 4.2).

b. Conformance inspection (see 4.3).

4.2 First article inspection. First article inspection, when specified, shall be performed by

the contractor, after award of contract, and prior to production, at a location acceptable to the

government (see 6.3). First article inspection shall be performed on sample units that have been

produced with equipment and procedures to be used in production (see 3.2).

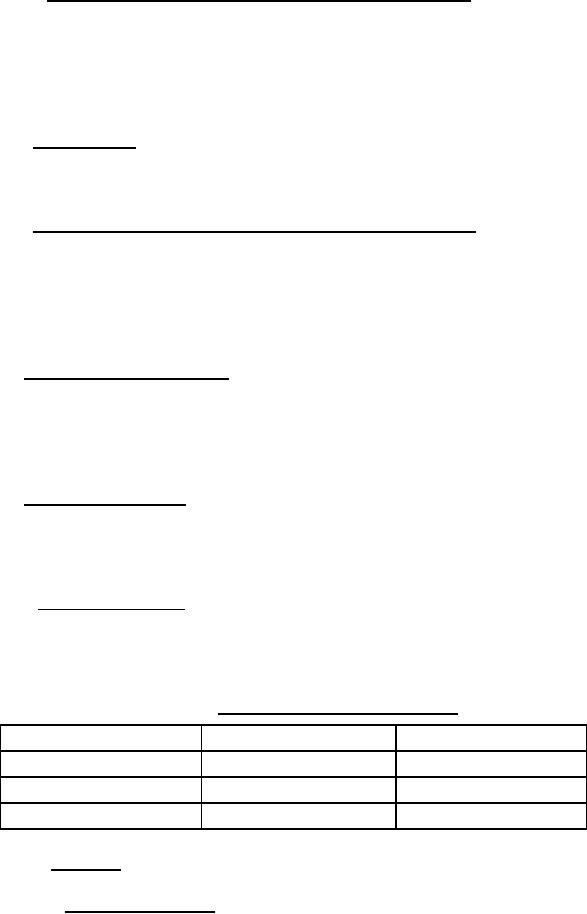

4.2.1 Materials inspection. Material inspection shall consist of the tests in table III and

any other tests required. Other material inspections not in table III shall consist of test data

certification by the contractor that the materials meet the drawings and other procurement

documents for the cable assembly, as applicable (see 6.2).

TABLE III. Material inspection requirements.

Test requirement

Requirement paragraph

Test method paragraph

Cable re-verification

Durometer hardness

Material reversion

4.2.1.1 Sampling.

4.2.1.1.1 Cable re-verification. A specimen shall be selected from every length of bulk

cable to be used in the manufacture of the assemblies, except for pre-cut cable lengths which shall

have specimens selected on a sampling basis with an acceptance quality limit (AQL) as specified

in the contract (see 6.2).

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business